Table of Contents:

10.Conclusion

Here’s a summary in case you don’t have time to read the whole article:

Every organization wants to be successful, but how success is measured can differ based on factors like company size, industry, or department. To quantify success, key performance indicators (KPIs) are widely used to track employee performance and identify those who actively contribute to organizational growth.

In procurement, having the right KPIs in place is critical to evaluating overall performance. If the wrong KPIs are used, however, procurement efforts could go awry. For example, measuring productivity based on per-employee spend can be misleading. Some employees might manage many suppliers with lower costs, while others could handle fewer suppliers but with higher spends. Without the right KPIs, procurement efforts could unintentionally lead to inefficiency.

In this article, we will explore the cost reduction KPIs, cost avoidance KPIs, and how platforms like Prokuria can help optimize procurement processes and achieve savings.

The Focus on Cost Savings

While a well-rounded procurement strategy covers several important areas, cost savings is the ultimate goal. Why focus on the procurement process unless the aim is to acquire necessary goods and services at the lowest possible cost?

What distinguishes high-performing procurement teams from average ones is the ability to deliver cost savings. Procurement software pricing and vendor management system pricing contribute to making procurement more efficient by streamlining processes, reducing overhead, and improving vendor negotiations.

Statistically, effective procurement professionals spend about 21% less money and employ 29% fewer people than their less efficient counterparts. The best procurement strategies focus on conserving financial resources by emphasizing both cost reduction KPIs and cost avoidance KPIs.

What are the Cost Reduction and Cost Avoidance KPIs?

When it comes to procurement, tracking cost reduction KPIs and cost avoidance KPIs is essential to optimizing your procurement strategy. Below are some key procurement metrics you should focus on to maximize your savings:

Key Procurement KPIs to Track:

Procurement ROI (Return on Investment)

Often considered the most important KPI for procurement, procurement ROI is calculated by dividing annual cost savings by internal procurement costs. It’s typically evaluated in combination with other metrics for a more comprehensive understanding of procurement performance.

Calculating the procurement ROI involves dividing the annual cost savings by the internal procurement cost. In general, this metric is best suited for your internal spend analysis and helps you determine the overall profitability, as well as the cost saving benefits of an investment or procurement function.

Price Competitiveness

In most cases where there is minimal vendor competition, there will also be a chance for supplier monopoly. In time, this can lead to lower-quality services and fewer growth opportunities for your company. The focus of this KPI is put directly on shortlisting only those vendors that offer your organization a competitive advantage. In a sense, it measures vendor performance.

Cost Reduction KPI

Tracks the hard savings achieved by comparing new procurement costs to previous costs. A continuous focus on cost reduction allows procurement teams to improve long-term efficiency and save on expenditures.

Cost Avoidance KPI

Focuses on savings achieved through strategic actions that prevent future costs. These "soft savings" may not directly impact the income statement but have significant long-term benefits.

Regardless, these soft savings can have a significant impact on the bottom line, even if they don't directly impact the income statement. These soft savings can include things such as various strategic investments that have no real comparisons. When combined with the cost reduction KPI, your procurement team can avoid future extra costs down the line.

Spend Under Management (SUM)

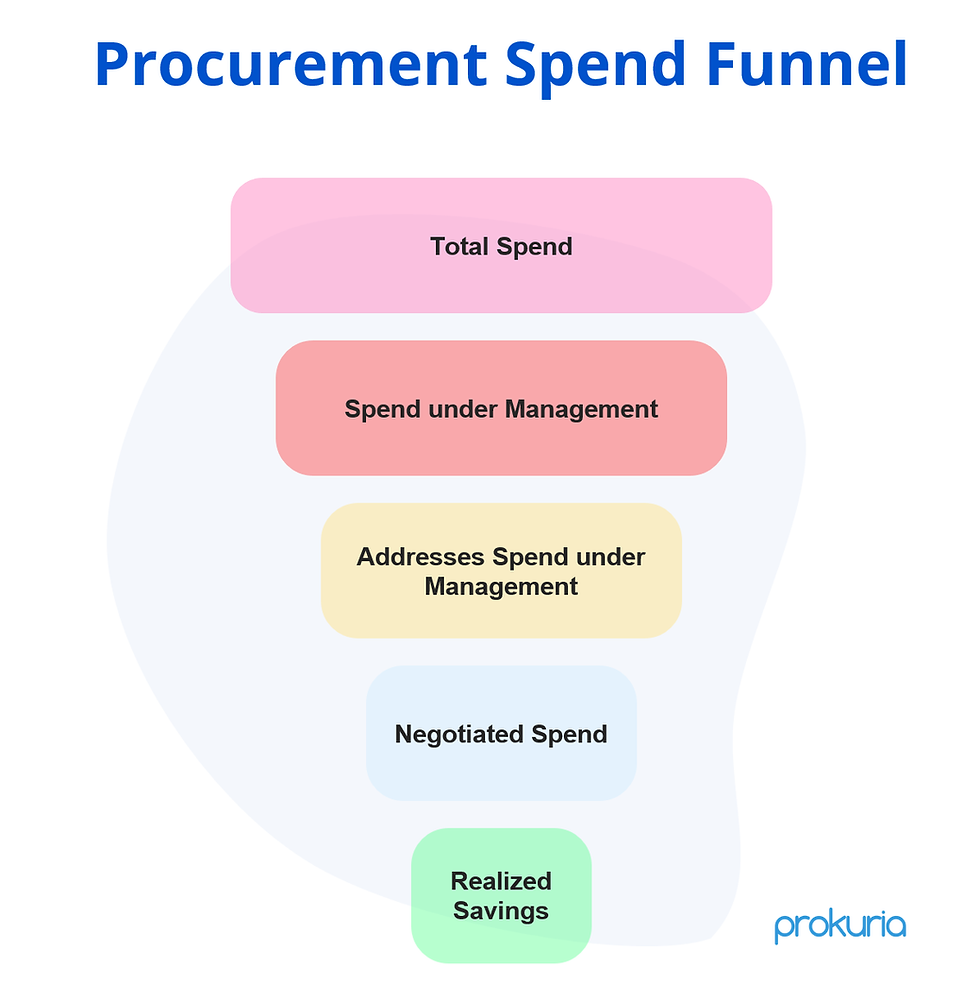

This metric tracks the percentage of procurement spending controlled by the procurement team. The greater the percentage of spend under management, the better your ability to forecast costs and optimize procurement decisions.

How Prokuria Can Help

Knowing the cost reduction KPIs and cost avoidance KPIs is one thing, but effectively implementing them requires the right tools. This is where procurement software like Prokuria comes into play.

Here’s how Prokuria can help optimize procurement performance and improve your cost-saving efforts:

Empowering your Supplier Negotiation Capabilities with Actionable Data - Prokuria consolidates data from all suppliers, providing real-time access to valuable insights. With this information, procurement teams can negotiate better prices and payment terms, effectively reducing costs across the organization. Vendor management system pricing plays a major role here by providing accurate data on vendor performance. A supplier relationship management (SRM) platform such as Prokuria will allow you to uncover any existing hidden costs by connecting all supplier data into a single, centralized location.

Using sourcing RFQs, RFPs, and RFIs - Prokuria’s platform makes the RFI RFP RFQ process more efficient. It helps you discover new suppliers, monitor your suppliers in real-time, benchmark existing ones, and gain a deeper understanding of the market. With Prokuria, you can easily compare suppliers based on key metrics, ensuring you choose the best options for your procurement needs.

Using Reverse Auctions - Prokuria’s reverse auctions allow you to increase competition between suppliers, driving down prices and improving payment terms. While e-auctions can be applied to pretty much every purchase your company makes, you are not obligated to do so every time. These auctions are highly effective at creating a competitive environment where vendors are motivated to offer the best possible deals, contributing directly to cost reduction KPIs.

By using Prokuria’s procurement software, your team can monitor these KPIs and continuously optimize supplier relationships, ultimately driving cost reduction and ensuring the best value for your procurement investments.

Conclusion

Establishing the right KPIs for procurement is key to ensuring that your procurement department is adding measurable value to the organization. Cost reduction KPIs, cost avoidance KPIs, and sourcing KPIs should be tracked regularly to ensure that procurement activities are aligned with your financial objectives.

By implementing Prokuria’s vendor management system and procurement tools, your team can effectively manage these KPIs, improve supplier negotiations, and deliver long-term cost savings across your organization.

Comments